COP27: Time to switch to more responsible solar

Empowered communities, consumers and corporations are key in reducing carbon emissions and abating climate change. More than ever, people and communities around the world are showing their discontent about the lack of progress in reducing greenhouse gas emissions and addressing climate change. Frequent natural disasters around the globe caused by rising temperatures are increasingly affecting people and local communities. Moreover, the impacts of climate change put almost every child at risk.1

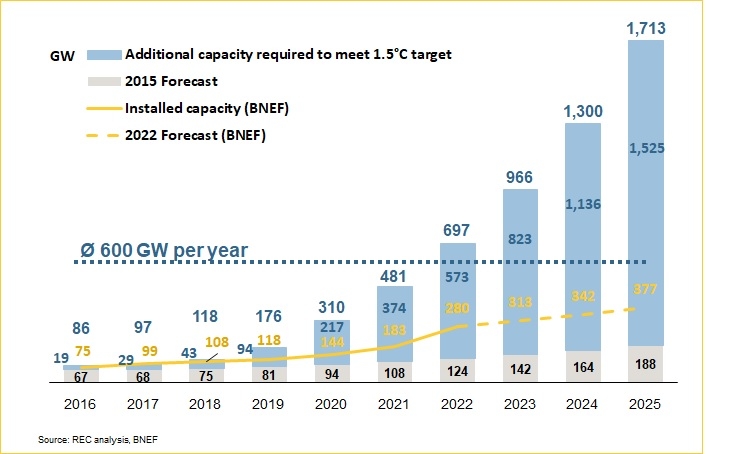

It is without any doubt that solar is one of the key pillars in decarbonizing our world. But, according to REC Group’s study2 right after the Paris Agreement ‘Closing the COP21 Gap by Going Solar’ it takes 500 to 600 GW of new solar PV capacity per year on average, which is the equivalent of 1.2 to 1.5 billion solar panels of 400 Wp power.

With these numbers, we at REC believe that as the solar industry grows in importance, so does our responsibility too and we need to be more ambitious. Determined to contribute to a cleaner and safer future for all, since our foundation more than 25 years ago in Norway, REC has sought to combine high-efficiency innovations with sustainable manufacturing and equitable work practices to better support communities and corporations with their energy transition.

We have identified four key pillars for the solar industry in order to make a greener contribution:

- Module Efficiency

- Resource Consumption

- Longevity

- Circularity

1. Increase efficiencies by going for most advanced technologies

As an early-mover, REC made years ago a bold decision to go for Heterojunction Cell Technology (HJT) on a large scale and introduced its award-wining Alpha Series in 2019. With HJT, REC combines the benefits of crystalline silicon solar cells with those of thin film technologies for higher efficiency and energy yield. REC’s latest HJT innovation, the REC Alpha Pure-R Series, offers 10% higher power output compared to conventional rooftop panels.3 Being part of Reliance Industries Limited and its New Energy push, REC is also taking a deep look at Perovskites as the next big solar technology. It is expected that Perovskite cell technology will enable up to 20% more energy over the 25-year lifetime of a solar project at significantly lower installed cost.4

2. Reduce resource consumption to limit own environmental footprint

Despite demonstrating an Energy Payback Time of less than one year already in 2011 by REC, manufacturing solar panels consumes a relevant amount of energy and water. That’s why we at REC have been running Energy, Water and Waste Saving Programs for many years. With various measures, such as chiller optimization, own solar rooftop installation or reverse osmosis reject water recycling, REC was able to save almost 7,000 MWh (equivalent of 660 homes’ annual power use in the US5), close to 3,000 t of CO2 emissions (1,500 t of coal not burned6 and almost 130,000 m3 of water (annual water usage of 2,200 people) in 2021 at its cell and module production site in Singapore. Lead in solar panels can become a serious waste issue once the panel reaches its end-of-life, despite a marginal average content of 24 g lead per panel. But if you fast forward, the total production of 460 million panels in 2021 alone will add 11,000 t of lead to the ecosystem. Going for lead-free solar panels, such as the Alpha Pure, is therefore another important contribution. Considering that REC has only a tiny 1% market share of the total global solar PV capacity, these measures show the incredible green potential for the whole industry.

3. Increase longevity of solar panels at a high and stable performance

The best recycling is the one which you do not need. Therefore, a long-lasting high performance and stability of solar panels for 25, 30 and more years make a significant difference. A solar panel itself has to withstand high wind and snow loads of up to 7,000 Pa, making it suitable for installations in high-altitude regions. On the other hand, a low temperature coefficient of -0.26%/°C allows the panel to perform well even under hot climate conditions– an aspect which will become even more critical in the future considering the clear climate warming. A low claims rate of well below 100 ppm indicates consumers which solar panel brand they can trust. As going solar is a long-term investment, warranted long-lasting performance pays off. REC for example guarantees 92% of the nominal power of its Alpha Pure solar panels in year 25 under the REC ProTrust warranty.

4. Increase circularity within own production and for end-of-life products

The production of silicon feedstock contributes in a significant way to the total carbon footprint of a solar panel, making around 60%. At its silicon production site in Norway, REC invented a new process technology to recycle silicon kerf, a byproduct of the wafer sewing process, and put it back into the solar PV value chain. This innovation reduces the carbon footprint of silicon by 95% compared to the conventional Siemens process. Another key aspect of a greener solar industry is the need to work on better recycling of end-of-life solar panels. Solar PV waste is projected to grow to 27 million tons per annum by 2040.7 Despite a low volume of only 19,000 scraped solar panels in 2021, REC is paying significant attention to a proper recycling of these and extracting in particular Aluminum, Copper and Silver for reuse. However, capabilities of today’s recycling technology are limited in terms of processes and volume. Considering the projected solar PV waste, more investments into advanced recycling sites and stricter requirements on a national level worldwide have to be done.

While the solar PV industry is heading into the right direction of a strong support of energy transition and mitigating climate change, with 300 GW of expected solar PV installations in 2023, we still have a good way to go to reach the required 500-600 GW per year and be on track for the 1.5°C path. At REC, we are confident and optimistic that we can do this but at the same time we have to call for a more responsible solar industry.

1 https://www.unicef.org/stories/impacts-climate-change-put-almost-every-child-risk

2 In its study, REC developed an ambitious expansion plan for solar PV in order to be on track of the emissions gap compatible with the 1.5°C goal within 10 years, so by 2025.

3 Comparing 430 Wp Alpha Pure-R with a 390 Wp monocrystalline full-black panel.

4 https://www.ril.com/DownloadFiles/CorporateAnnouncements/MR23092022.pdf

5 EPA Greenhouse Gas Equivalencies Calculator

6 EPA Greenhouse Gas Equivalencies Calculator

7 Rystad Energy